WIR ARBEITEN FÜR:

2. Stammstrecke Munich

The 2nd trunk line represents a significant extension of the existing S-Bahn system and includes the construction of an additional tunnel section running about 7 kilometres under Munich's city centre...

Description

The 2nd trunk line represents a significant extension of the existing S-Bahn system and includes the construction of an additional tunnel section running about 7 kilometres under Munich's city centre. This tunnel runs parallel to the existing main line and creates an important connection between the main station and the Ostbahnhof. The aim of this project is to relieve the existing S-Bahn line and improve public transport in Munich.

The implementation of the project poses some unique challenges, including construction under existing long-distance lines, underground lines and in close proximity to important buildings such as Munich's main railway station and historic structures such as the Frauenkirche in the city centre.

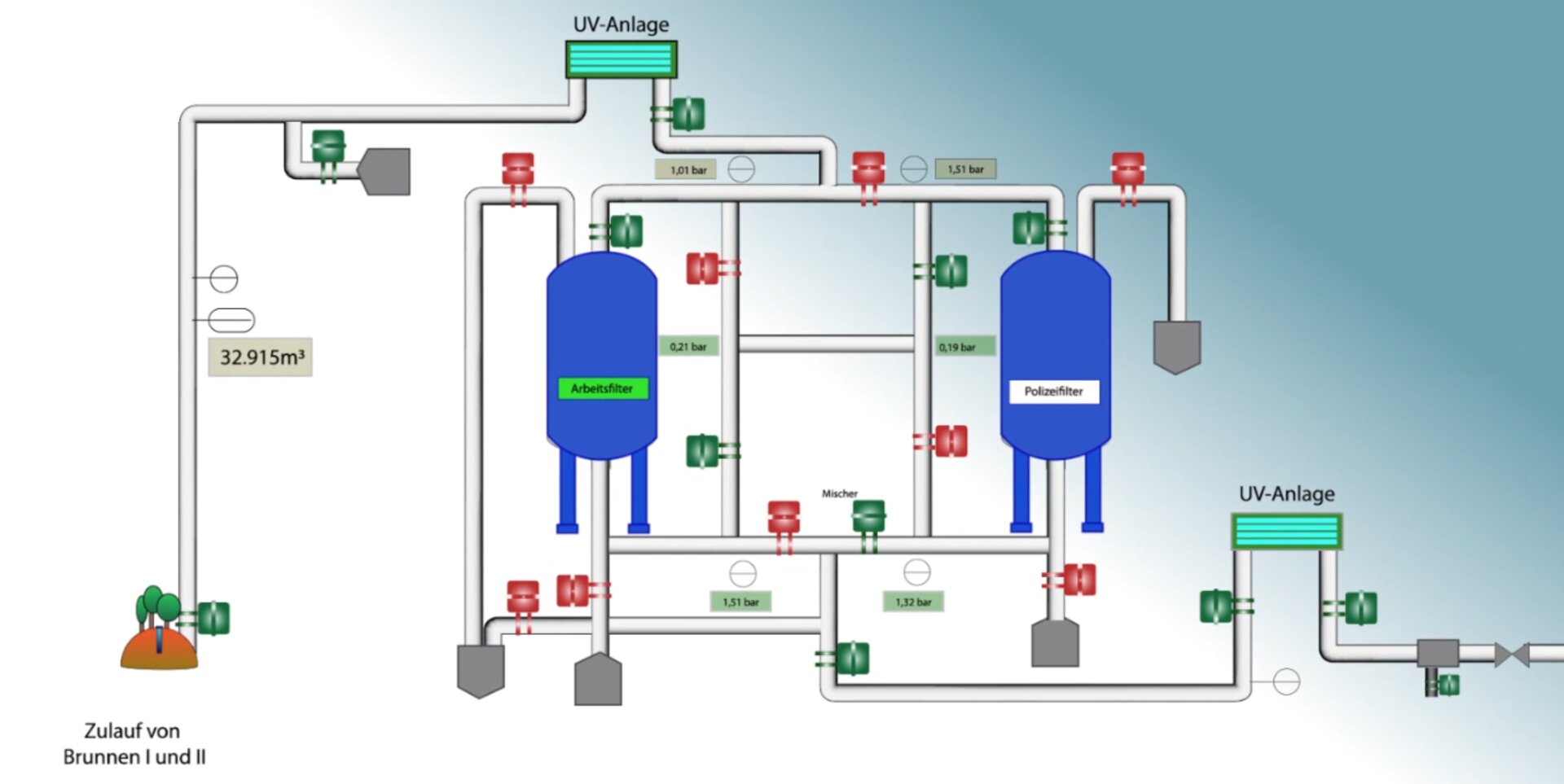

To ensure that our project partners and everyone involved keep their feet dry during construction, we rely on extensive dewatering measures. These include around 6 km of penstocks, 170 groundwater drawdown wells and 18 infiltration wells, as well as around 150 control gauges in conjunction with a real-time monitoring system. In addition, we operate four plants with sedimentation basins for sediment separation and pH neutralisation for the purification of day-stratified and groundwater from the open dewatering wells. Since March 2019, we have been responsible for all the dewatering activities in this project.

Our task is to ensure the smooth running of the project while protecting the environment and existing infrastructures.

Data & Facts

- VE 41: Marienhof station

- VE 30 with subcontracting units

EIS 30.1: Tunnel and trough structure and rescue shafts

EIS 30.2: Main railway station

EIS 30.7: Groundwater drainage and infiltration system

- Dewatering and groundwater relief to depths of 60 m

- 4 Water treatment plant (WAA) with settling basin and pH neutralisation

- Groundwater infiltration system up to 430 m³/h

- Extensive online groundwater management and process control system

Pictures:

1. DB Netz AG/panterra.tv

2. DB AG/panterra.tv

3. Hölscher Wasserbau GmbH